Star Proof offers new features for packaging applications that

able simulate the plate dot characteristics of flexo printing

to ensure that your proofs accurately reflect what will be

produced on the press.

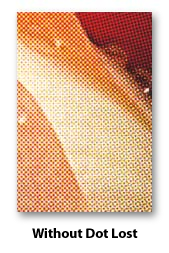

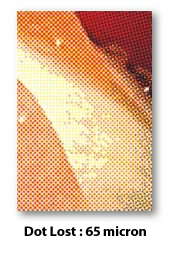

Screening dots prepared for flexo plates are normally adjusted

in width or height by a small percentage to compensate for

expansion during printing. Star Proof Distortion expands

distorted dots to the original size with user controls to correct

the size of the screening dots based on the original distortion

ratio or the expansion ratio. Star Proof also compensates

for the lost of small dots in the transfer to flexo plates during

plate making. By entering a Dot Lost size, any screening

dots smaller than this size will be removed and will not appear

on the proof.

Flexo printing, especially for printing on corrugated media, has extremely high dot gain of up to 15% to 20% and normal dot gain adjustment cannot compensate dot gains of this magnitude. Star Proof’s Extreme Dot Gain increases screening dot size dramatically by adding a border of 1 or more pixels around the screening dot - again, giving you the confidence that what you see on your proof matches the press.

separation

separation

trapping

Star Plate